In the world of industrial machinery, gears are the unsung heroes that keep everything moving. Whether it’s manufacturing plants, mining operations, or energy generation, industrial gears play an essential role in delivering power, precision, and efficiency. Understanding how these gears work, and where they are used, gives us insight into how modern industries function seamlessly.

Types of Industrial Gears

Different applications require different types of gears. Some common types used in industrial machinery include:

- Spur Gears: The most straightforward type, spur gears, have straight teeth and are commonly used in low-speed operations. Their simple design makes them easy to manufacture and cost-effective.

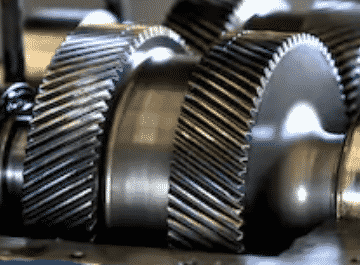

- Helical Gears: These gears have teeth that are cut at an angle, allowing for smoother operation and higher speeds than spur gears. They are often found in automotive transmissions and other applications requiring quiet and efficient movement.

- Bevel Gears: Designed for transmitting motion between intersecting shafts, bevel gears are used in differentials, power tools, and elevators. Their conical design allows for angular movement, making them suitable for versatile applications.

- Worm Gears: Known for their ability to reduce speed and increase torque, worm gears are found in conveyors, lifts, and heavy-duty machinery. Their self-locking property adds an extra layer of safety in certain applications.

Applications of Industrial Gears

The versatility of gears means they are used across a wide range of industries:

- Manufacturing: Gears are used in presses, conveyors, and robotic arms, driving production lines and ensuring precision in assembling parts.

- Energy Sector: From wind turbines to hydroelectric plants, gears play a critical role in converting mechanical energy into electrical power. They enhance efficiency in large-scale power generation equipment.

- Automotive Industry: Gears form the backbone of vehicle transmissions, allowing smooth power transfer between the engine and wheels. The performance of cars, trucks, and even heavy machinery depends heavily on gear systems.

- Aerospace: In this high-stakes industry, precision gears are used in turbines, control systems, and landing gear mechanisms. They ensure safety and reliability, even under extreme conditions.

The Future of Gears: Innovation and Sustainability

As industries continue to evolve, so too do the demands on industrial gears. Today, companies are focusing on innovations that increase the efficiency and lifespan of gears. One area of development is material science, where lightweight yet durable materials are being explored to reduce wear and tear.

Furthermore, the push towards sustainability is influencing gear design. Energy-efficient gears, which reduce friction losses and enhance performance, are becoming increasingly vital in reducing carbon footprints across industries.

Conclusion

Industrial gears are the backbone of countless machines and processes, ensuring that everything runs smoothly. Their wide range of applications, from heavy machinery to precision tools, highlights their importance in modern industry. As technological advancements continue to push the boundaries, the role of gears will only become more critical, driving efficiency, sustainability, and innovation in the industrial world.

Want to improve your machinery’s performance with cutting-edge gears? Contact us today for customized gear solutions!