In the world of heavy industries, where efficiency, precision, and reliability are crucial, industrial gearboxes play an indispensable role. From manufacturing plants to power stations, gearboxes are the unsung heroes behind countless machines, ensuring optimal performance by controlling speed, torque, and mechanical power transmission. At Stelco Gears, we specialize in crafting high-quality gearboxes designed to meet the rigorous demands of industrial applications. But what exactly makes gearboxes so essential

What Is an Industrial Gearbox?

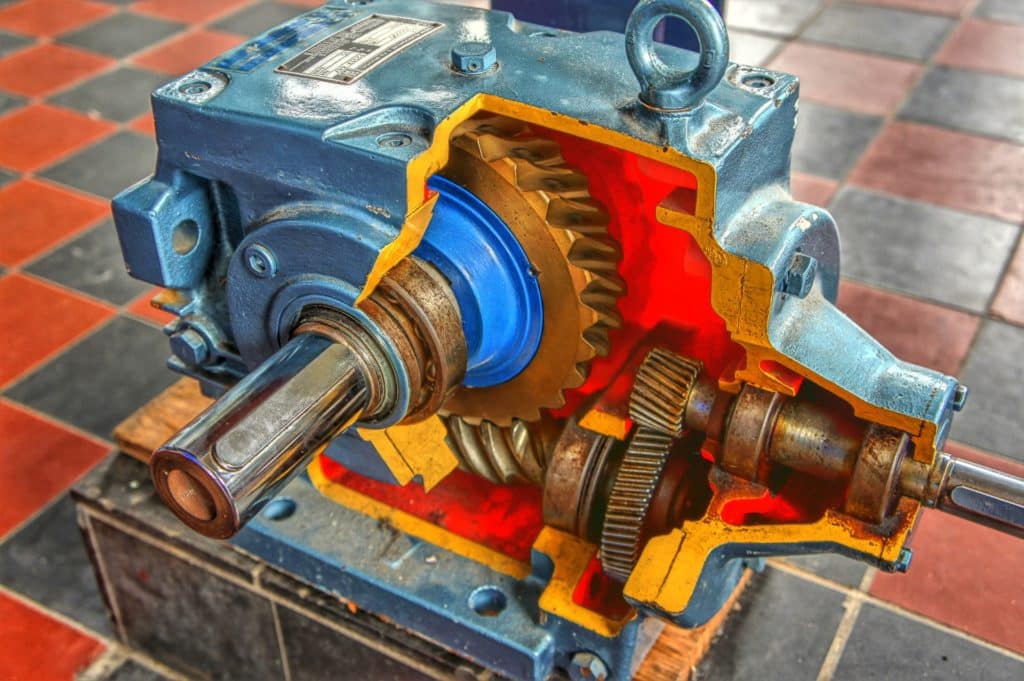

An industrial gearbox is a mechanical device used to transfer energy between machines, adjusting speed and torque to suit different applications. Whether it’s in steel production, mining, power generation, or automotive assembly lines, gearboxes help maintain the efficiency and stability of machines by managing the output based on the mechanical input.

Key Types of Industrial Gearboxes

- Helical Gearbox: Helical gearboxes are known for their smooth, quiet operation and are commonly used in heavy-duty applications. Their angled teeth enable more contact points, ensuring better load handling. These gearboxes are ideal for crushers, extruders, conveyors, and mixers.

- Bevel Gearbox: A bevel gearbox is used to change the direction of the shaft’s rotation. It’s perfect for differential drives and conveyor systems, where torque needs to be efficiently transferred between different machinery.

- Worm Gearbox: With a high reduction ratio, worm gearboxes are known for their compactness and ability to handle heavy torque loads. These gearboxes are often found in lifts, elevators, and heavy manufacturing machinery where space is limited but power transmission is key.

- Planetary Gearbox: Planetary gearboxes offer a higher torque-to-weight ratio and are highly efficient. Used in automotive, mining, and aerospace industries, they provide high precision and control in high-load operations.

- Industrial Spur Gearbox: Spur gearboxes are typically used in low-speed applications due to their simple design. They are highly efficient and offer cost-effective solutions for industries where speed reduction is crucial.

Why Quality Gearboxes Matter in Industrial Settings

The performance of industrial machinery largely depends on the reliability of its components, and gearboxes are at the heart of most operations. A poorly designed gearbox can lead to downtime, increased maintenance costs, and even catastrophic failures. That’s why industries need to invest in high-quality, durable gearboxes to keep operations running smoothly and efficiently.

At Stelco Gears, we understand the importance of precision and durability in industrial applications. Our gearboxes are designed using the latest engineering techniques and high-grade materials, ensuring that they can withstand the toughest conditions, from extreme heat to high-torque loads. We offer customized solutions tailored to the specific needs of your industry.

Key Benefits of Stelco Gears’ Industrial Gearboxes:

- High Efficiency: Our gearboxes are designed to minimize energy loss, reducing operational costs.

- Durability: Built to handle the most demanding industrial environments, our gearboxes are long-lasting and require minimal maintenance.

- Precision Engineering: With exacting standards, we ensure that every gearbox performs at optimal levels, reducing downtime.

- Custom Solutions: Whether you need a standard model or a customized solution, Stelco Gears can design a gearbox that fits your unique requirements.

Conclusion

Industrial gearboxes are vital components in keeping machinery running efficiently. By selecting high-quality gearboxes from trusted manufacturers like Stelco Gears, industries can boost productivity, reduce maintenance costs, and ensure smooth operations.

Looking for the right gearbox for your industrial needs? Contact us today at Stelco Gears to explore our wide range of industrial gearboxes or visit our website to learn more!