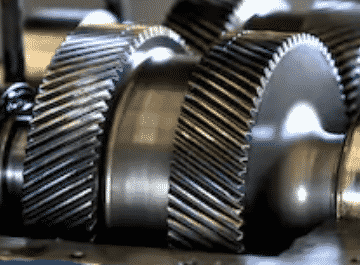

In the world of industrial machinery, gears play a pivotal role in transmitting power and ensuring smooth operations. Among the various types of gears, helical gears stand out due to their versatility, efficiency, and ability to handle heavy loads. At Stelco Gears, we specialize in the manufacturing of high-quality helical gears designed to meet the demands of diverse industrial applications.

What Are Helical Gears?

Helical gears have teeth that are cut at an angle to the face of the gear, unlike spur gears which have straight teeth. This design allows for gradual engagement of the teeth, resulting in smoother and quieter operation. The angled teeth of helical gears enable them to handle higher loads and reduce noise levels, making them ideal for industries where precision and quiet operation are critical.

Key Features and Benefits of Helical Gears

- Smooth Operation: Helical gears provide a more gradual engagement compared to other gear types, reducing shock loads and vibrations. This smooth operation is crucial in applications such as conveyors, compressors, and automotive systems, where seamless power transmission is essential.

- High Load Capacity: Due to the helical design, these gears can transmit larger amounts of power between shafts. They are commonly used in heavy machinery and industrial equipment where high load capacities are required.

- Durability: At Stelco Gears, our helical gears are crafted from high-strength materials, ensuring long-lasting performance even in the most demanding environments. Their durability makes them ideal for industries like mining, construction, and power generation.

- Versatile Applications: Helical gears are used in a wide range of industries, from automotive to aerospace and manufacturing. Their ability to handle both radial and axial loads makes them suitable for applications where high precision and efficiency are required.

- Noise Reduction: The angled teeth of helical gears make them significantly quieter than spur gears, reducing noise pollution in industrial environments. This is especially beneficial in sectors such as textile manufacturing and food processing, where quiet operations are essential for maintaining a safe and comfortable work environment.

Helical Gears in Indian Industries

In India, industries are rapidly evolving with advancements in automation and manufacturing technologies. Helical gears are becoming increasingly important in sectors such as automobile manufacturing, cement plants, and steel mills, where precision and reliability are key. At Stelco Gears, we understand the unique requirements of the Indian market and offer customized helical gears that meet the highest standards of quality and performance.

Why Choose Stelco Gears for Your Helical Gear Needs?

- Custom Solutions: We offer custom-designed helical gears that are tailored to meet the specific needs of your machinery. Whether you need gears for high-speed applications or heavy-duty equipment, Stelco Gears has the expertise to deliver the perfect solution.

- Precision Engineering: Our helical gears are manufactured using advanced technology and precision engineering, ensuring consistent performance and long-lasting durability. We adhere to strict quality control standards to deliver gears that exceed industry expectations.

- Support and Service: At Stelco Gears, we don’t just provide products; we offer ongoing support and consultation to ensure that your machinery operates at peak efficiency. Our team of experts is always available to assist with gear selection, installation, and maintenance.

Conclusion

Helical gears are an essential component in many industrial applications due to their versatility, durability, and ability to handle heavy loads with minimal noise. At Stelco Gears, we take pride in providing high-quality helical gears that meet the specific needs of various industries. Whether you are in automotive, manufacturing, or power generation, our custom gear solutions ensure optimal performance and reliability.

Explore our range of helical gears today and discover how Stelco Gears can enhance your machinery’s efficiency and longevity.