High-Performance Girth Gears by Stelco Gears

Unmatched Precision and Durability

Unmatched Precision and Durability

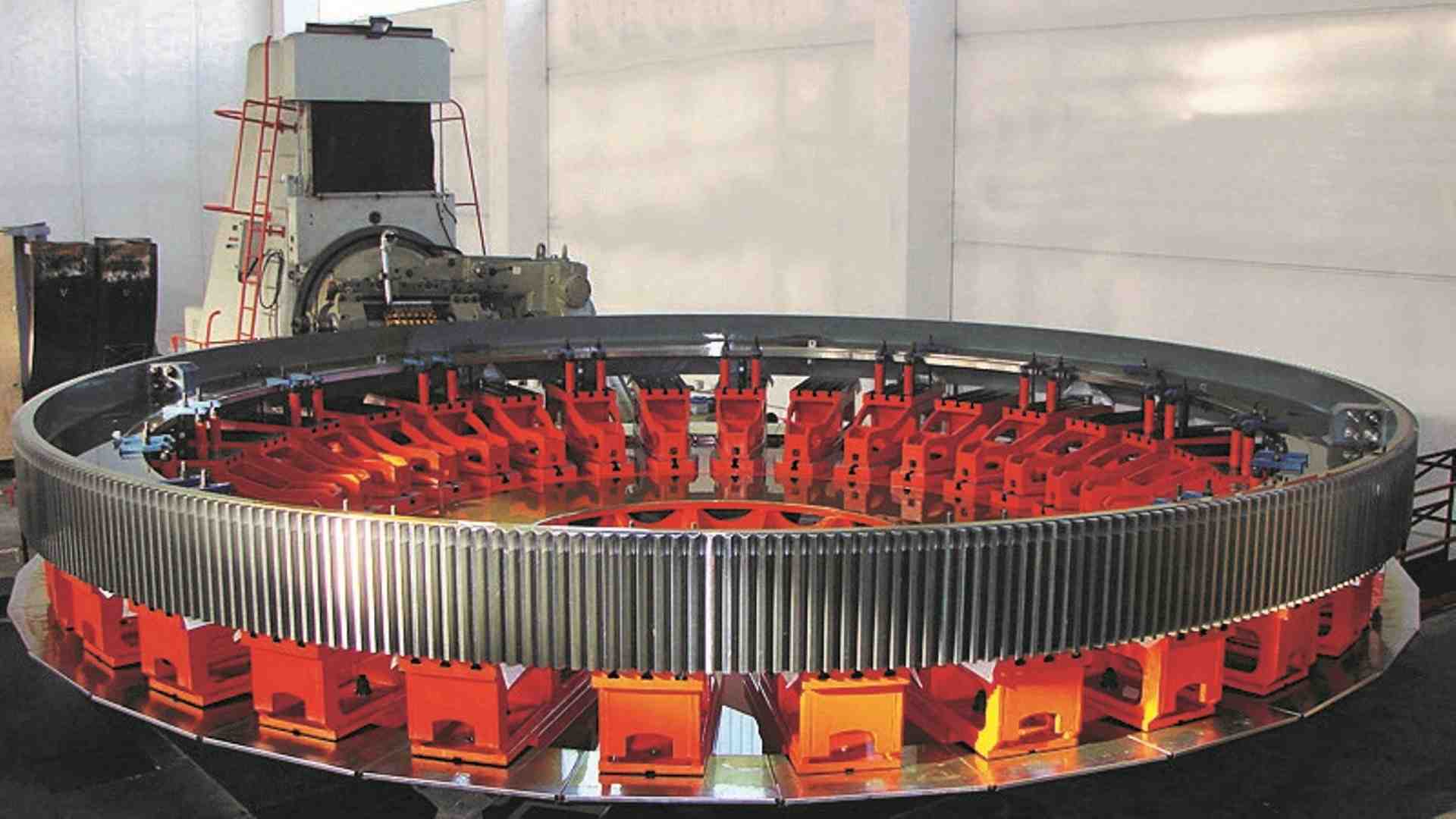

Stelco Gears takes pride in manufacturing top-grade girth gears, engineered to deliver maximum efficiency and reliability across various industrial applications. Our girth gears are crafted to handle the demanding torque and rotational forces required in heavy-duty operations, providing durability and precision to ensure smooth operation over extended periods.

Key Features and Benefits

Premium Quality Materials

We use only the highest quality alloy steel and cast iron to ensure outstanding strength and durability. Each girth gear undergoes stringent material testing to meet industrial-grade standards.

High Precision Engineering

Advanced CNC machining ensures our girth gears are manufactured with impeccable accuracy, resulting in smooth performance and reduced operational downtime.

Custom Design Options

With diverse design capabilities, we offer tailored girth gear solutions suited to specific machinery and operational requirements, maximizing productivity and efficiency.

Enhanced Lifespan and Durability

Through our rigorous heat-treatment processes, our girth gears achieve increased wear resistance, reducing maintenance costs and downtime.

Technical Specifications

- Diameter Range: Our girth gears are available in a range of diameters, from 500mm to 9,000mm, to suit various industrial applications.

- Material Options: Available in high-grade alloy steel and cast iron, with options for additional surface treatments.

- Tolerances: We adhere to strict tolerances, ensuring each gear meets the precise specifications required for heavy-duty performance.

Manufacturing Process Overview

Our manufacturing process incorporates advanced technology at each stage, ensuring consistency, accuracy, and quality. From CNC machining to specialized heat treatment and material testing, each step is carefully controlled to produce girth gears with the durability and precision needed for critical industrial applications

Applications

Stelco Gears’ girth gears are designed for versatility and are widely used across multiple industries, including:

- Cement and Mining: Essential for driving large rotating kilns and mills, our gears offer stability and durability in challenging environments.

- Power Generation: Suitable for power plants and turbines, they ensure dependable energy production.

- Steel and Metal Processing: Ideal for large rolling mills, our girth gears enhance operational continuity and efficiency.

Commitment to Quality

At Stelco Gears, we adhere to strict quality standards throughout the production process, from material sourcing to final inspections. Our quality assurance team conducts comprehensive tests to ensure each girth gear meets international performance and safety standards.

Why Choose Stelco Gears?

With decades of expertise and a commitment to engineering excellence, Stelco Gears stands out in the industry. We deliver products that not only meet but exceed customer expectations, providing durable, efficient, and custom-fit solutions for any heavy-duty application.

Get in Touch

Explore how our high-performance girth gears can enhance your operations. Contact us today for a consultation and find out why leading industries trust Stelco Gears for reliability and precision.